- Overview

- Product Description

Basic Info.

Model NO.

WF-JF

Surface Processing

Spraying

Fine Blanking

Multi-Position

Process

Forming Process

Industry

Metal Stamping Parts

Tolerances

0.01mm

Customized

Customized

Item

Stamping Parts

Technics

Stamping

Part Type

Forming Parts

Export Markets

Global

Shipping Port

Qingdao

Place of Origin

China

Transport

by Sea or Air

Packing

Wooden Cases or Carton

Surface Treatment

Spraying/Polishing/Galvanized/Electroplating

Weight

Customized

Sample

7 Days Ready

Processing

as Per Your Drawing

Materials

as Per Request

After-Sale Service

Definetly

Certificate of Origin

as Per Request

Transport Package

Plywood Box

Specification

As your requirement

Trademark

jufeng

Origin

Weifang City, Shandong Province, China

HS Code

7326199000

Production Capacity

10000PCS/Month

Product Description

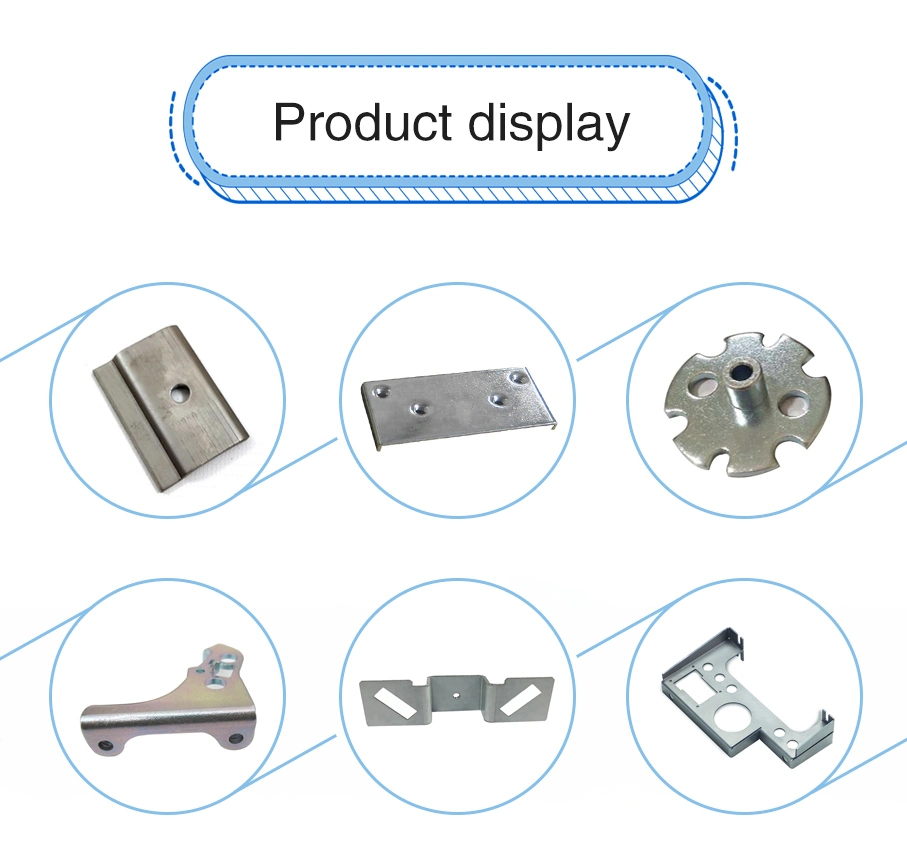

Wholesale Aluminum Parts Stamping Clamp Metal Side Bracket Metal Frame for Electronics

Q: What is the payment method?

Q: What is the payment method?

A: We accept TT (Bank Transfer), Western Union, L/C.

1. For total amount under US$500, 100% in advance.

2. For total amount above US$500, 30% in advance, the rest before shipment.

Q: What is your MOQ?

A: MOQ depends on our client's needs, besides, we welcome trial order before mass-production.

Q: What is the production cycle?

A: It varies a lot depending on product dimension,technical requirements and quantity.

We always try to meet customers' requirement by adjusting our workshop schedule.

Q: What kind of payment terms do you accept?

A: T/T, western union, etc.

Q: Is it possible to know how is my product going on without visiting your company?

A: We will offer a detailed products schedule and send weekly reports with digital pictures

and videos which show the machining progress.

Q: If you make poor quality goods ,will you refund our fund?

A: We make products according to drawings or samples strictly until they reach your 100%

satisfaction.And actually we wont take a chance to do poor quality products.We are proud of

keeping the spirit of good quality.

Quality First, Price Best, Service Foremost!

We assure you of our best services at all times!

| Material | Steel: Carbon steel/ Mild steel/ Cold roll steel/ Hot roll steel | ||

| Stainless : SS201, SS303, SS304, SS316 etc. | |||

| Aluminum: AL5052, AL6061, AL6063,AL7075 etc. | |||

| We handle many other type of materials. Please contact us if your required material is not listed above | |||

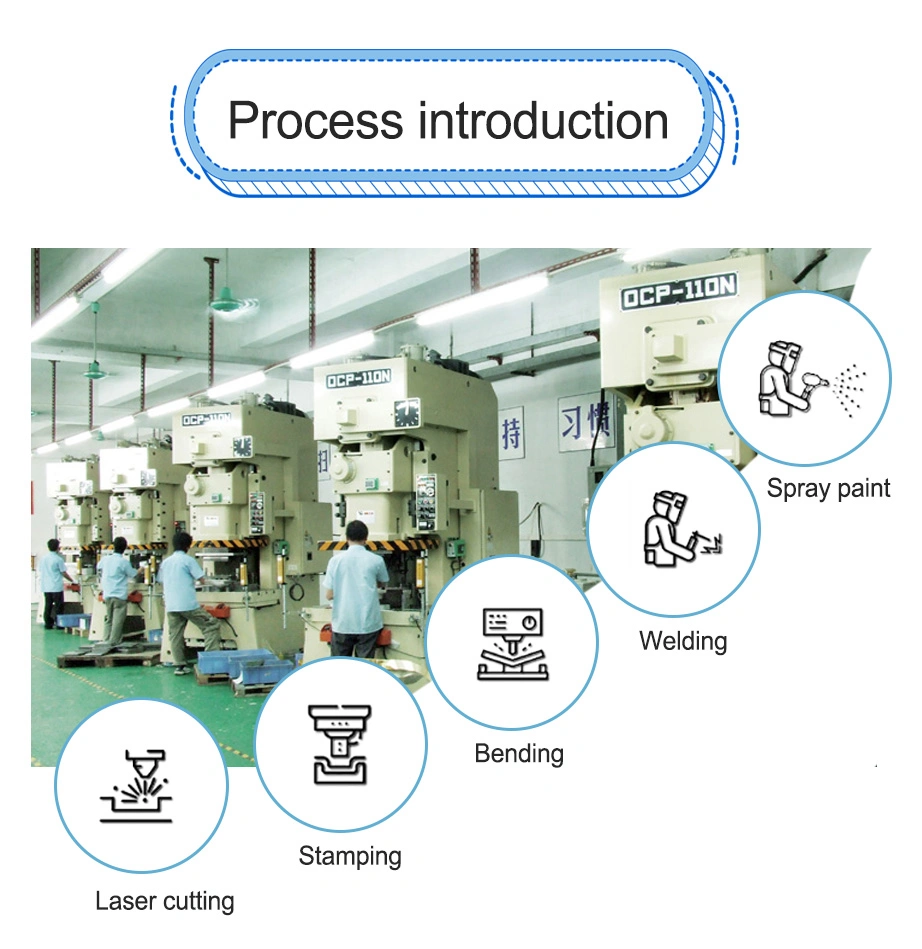

| Equipment | Laser Cutting Machines*2 | 40T-160T Stamping Machines | |

| CNC Shearing Machines*3 | CNC Turret Punching Machines*3 | ||

| CNC Forming Machines*3 | Air Pressure Squeeze Riveter | ||

| Welding Robot | CO2Gas Arc Welding Machine | ||

| Argon Arc Welding Machine | Swinging Arm Spot-welding Machine | ||

| Radial Drilling Machine | Horizontal Metal Band Sawing Machine | ||

| Precision CNC Shearing Machine | Aluminum Profile Super Efficient Automatic End Milling | ||

| Horizontal Shaft Table Surface Grinding Machine | |||

| Drawing format | PDF | DWG | STEP |

| JPG | IGS | SLD | |

| SLDPRT | DXF | | |

| Drawing Software | CASA | Solid works | CAD |

| Pro-cam | CAM-PATH | | |

| Processing | CNC punching | 3000 * 1500 mm(max) | |

| CNC Cutting | T≤12 mm, L≤3000 mm | ||

| Laser Cutting | T≤16 mm, 6000*2000(max) | ||

| CNC Bending | T≤10 mm, L≤4100 mm | ||

| Finishing | Powder coating | Polishing | Spraying |

| Galvanized(zinc-plated, nickel-plated,chrome-plated,silver-plated) | |||

| Customized | |||

| Tolerance | Stamping parts : 0.01-0.1mm | ||

| CNC machining parts : 0.002-0.1mm | |||

| Application | Auto parts | Medical Equipment | Electronic Products |

| Power switches | Storage | Electric Appliance | |

Material Acceptable

1: Shrink film+ bulk loading

2: Shrink film +Carton box + Pallet/ wooden case

3: PP + Wooden case

4: As per customers' requirements or negotiated

OUR PRODUCING PROCESS:

OUR PRODUCING PROCESS:

1. Tooling (Mold) design and Manufacture.

2. Manufacture the parts according to the Stamping Machine.

3. Riveting, Welding or Screw tap according to Customer's require.

4. After finish manufacture process we will test the parts by the Image measurement instrument, Caliper,

Angel Gage etc.

5. After make sure all the dimension can reach customer's require, we will make the surface treatment

process.

6. After finish surface treatment we will test all the parts by worker so that we can make sure the

parts which we sell is 100% qualified.

7. After finish testing we will pack the parts by Vacuum Package Machine.

| Aluminum | AL5052, AL6061, AL6063,AL7075 etc. |

| Stainless steel | SS201, SS303, SS304, SS316 etc |

| Brass | C36000 (C26800), C37700 (HPb59), C38500 (HPb58), C27200 (CuZn37), C28000 (CuZn40) etc |

| Bronze | C51000, C52100, C54400, etc. |

| Iron | 1213, 12L14, 1215 etc |

| Steel | Q235, 20#, 45# etc. |

Packaging Details:

Packaging Details:

1: Shrink film+ bulk loading2: Shrink film +Carton box + Pallet/ wooden case

3: PP + Wooden case

4: As per customers' requirements or negotiated

OUR PRODUCING PROCESS:

OUR PRODUCING PROCESS:1. Tooling (Mold) design and Manufacture.

2. Manufacture the parts according to the Stamping Machine.

3. Riveting, Welding or Screw tap according to Customer's require.

4. After finish manufacture process we will test the parts by the Image measurement instrument, Caliper,

Angel Gage etc.

5. After make sure all the dimension can reach customer's require, we will make the surface treatment

process.

6. After finish surface treatment we will test all the parts by worker so that we can make sure the

parts which we sell is 100% qualified.

7. After finish testing we will pack the parts by Vacuum Package Machine.

A: We accept TT (Bank Transfer), Western Union, L/C.

1. For total amount under US$500, 100% in advance.

2. For total amount above US$500, 30% in advance, the rest before shipment.

Q: What is your MOQ?

A: MOQ depends on our client's needs, besides, we welcome trial order before mass-production.

Q: What is the production cycle?

A: It varies a lot depending on product dimension,technical requirements and quantity.

We always try to meet customers' requirement by adjusting our workshop schedule.

Q: What kind of payment terms do you accept?

A: T/T, western union, etc.

Q: Is it possible to know how is my product going on without visiting your company?

A: We will offer a detailed products schedule and send weekly reports with digital pictures

and videos which show the machining progress.

Q: If you make poor quality goods ,will you refund our fund?

A: We make products according to drawings or samples strictly until they reach your 100%

satisfaction.And actually we wont take a chance to do poor quality products.We are proud of

keeping the spirit of good quality.

Quality First, Price Best, Service Foremost!

We assure you of our best services at all times!