- Overview

- Product Description

Basic Info.

Model NO.

WF-JF

Processing Type

Shaping Metal

Material

Carbon Steel

Mould

Multistep Progressive Dies

Surface Processing

Electroplating

Fine Blanking

Double Acting

Process

Forming Process

Industry

Metal Stamping Parts

Tolerances

0.02mm

Customized

Customized

Material Type

Carbon Steel/Stainless Steel

Name

Sheet Metal Stamping Parts

Place of Origin

Shandong, China

Technics

Stamping, Punching, Grinding

Quality Stardard

DIN/JIS/BS/ASTM/CE

R & D Service

Design and Drawing

Dimension

Customized

Unique

15 Years of Manufacturing

Technology

Casting + Machining

OEM and ODM

100% with Drawings and Samples

Delivery Time

30 Days After Payment

OEM Sample

About 10 Days

MOQ

2000 Pieces for Trial Order

OEM Package

Anti-Rust Package System

Inner Package

Carton Box/Plastic Bag

Transport Package

Pallet, Iron Frame, Flywood Box.

Specification

As your requirement

Trademark

Shengao

Origin

Weifang City, Shandong Province

HS Code

87089910

Production Capacity

50000PCS/Month

Packaging & Delivery

Package Size

100.00cm * 90.00cm * 80.00cm

Package Gross Weight

100.000kg

Product Description

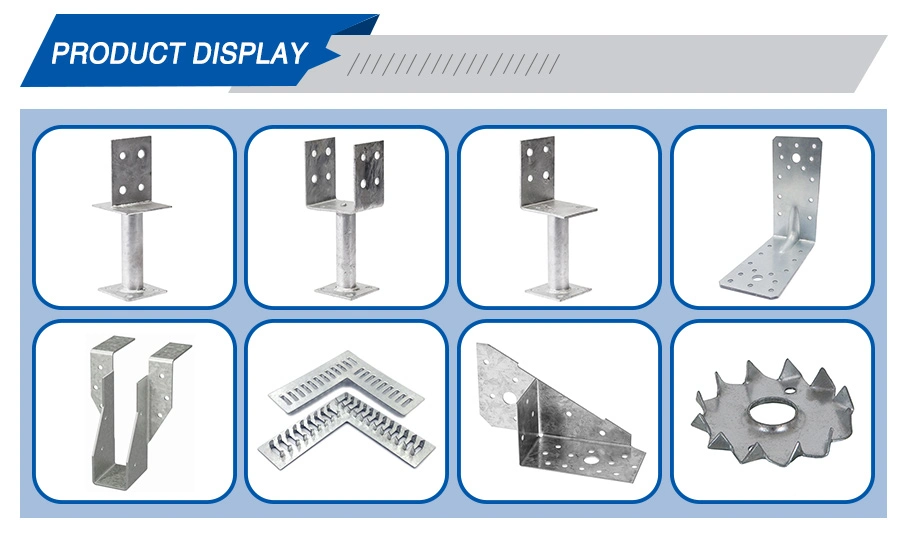

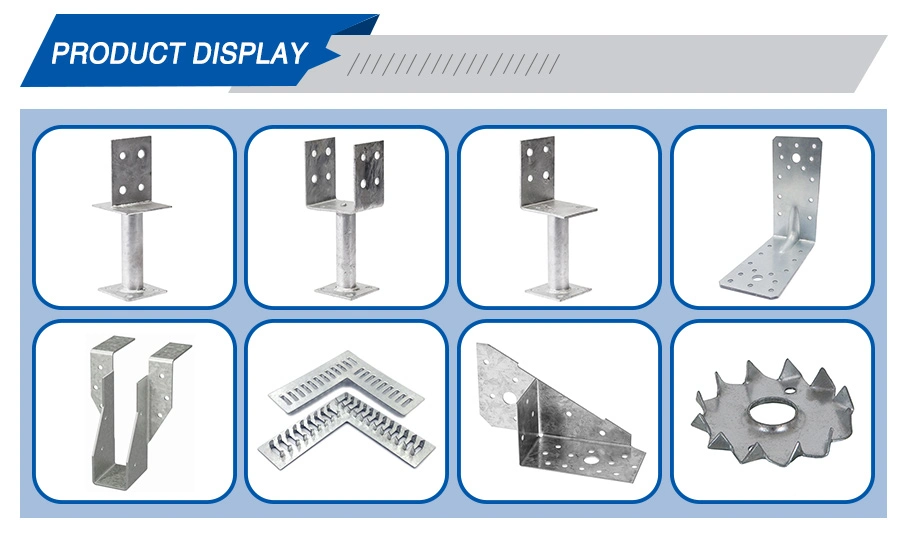

Timber Wooden Building Galvanized Steel Building Fitting

»Reasonable Pricing provided

»Competitive shipping cost service

»Small quantity order accepted

»Professional engineering service when any modification required

»Any assembly or customized package requirements could be accepted

*How to receive an online quotation?

*How to receive an online quotation?

Please send us your pictures or 3D drawings/2D drawings for us to check all the dimensions.

Specify your required material, surface treatment, quantity and other related information in the email.

We will handle it for you once receiving it soon!

Specifications:

Specifications:

1. Item: Sheet metal fabrication dustbin

2. material: steel plate

3. surface treatment: passivating

4. tolerance: +/- 0.1mm

5. process: Punching/pressing through stamping tooling

6. industrial: Metal stamping parts/punching parts/pressing parts

7. certificate: ISO 9001: 2008, SGS, Rohs.

OUR PRODUCING PROCESS:

OUR PRODUCING PROCESS:

1. Tooling (Mold) design and Manufacture.

2. Manufacture the parts according to the Stamping Machine.

3. Riveting, Welding or Screw tap according to Customer's require.

4. After finish manufacture process we will test the parts by the Image measurement instrument, Caliper, Angel

Gage etc.

5. After make sure all the dimension can reach customer's require, we will make the surface treatment process.

6. After finish surface treatment we will testing all the parts by worker so that we can make sure the parts

which we sell is 100% qualified.

7. After finish testing we will pack the parts by Vacuum Package Machine.

1. New product development process

1. New product development process

Got tooling order and sample order with 50% deposit---Hold a meeting with the relation dept. To ensure the developing schedule---Design mould, fixture and gauge and making them in our factory---mould, fixture and gauge making---producing samples---approved from customer-purchasing material-forging-heat treatment-shot blasting-machining-Inspection-package---delievry

2. Can we visit the factory to conduct an audit?

Yes, you are welcome to visit our factory.

3. How to handle the complains?

If happen any complaints after delivery,please just show us photos and detail compliants points, we will check with the production department and QC department Immediately and give you best solving solution which agreed by both of us,moreover we will bear all the cost (including shipping cost).

All parts are made according to customer's drawings or samples.If you have any parts to be made, please feel free to send your kind drawings/samples to us.Technical drawings including material mark, Product weight, Purchase quantity.The comprehensive information will help us quickly calculate the accurate and reasonable price for you.

You can look through our website to find your interest or email your any questions through below approach! We will reply to you within 12 hours.

»Reliable Stamping service

»Good production quality»Reasonable Pricing provided

»Competitive shipping cost service

»Small quantity order accepted

»Professional engineering service when any modification required

»Any assembly or customized package requirements could be accepted

*How to receive an online quotation?

*How to receive an online quotation?Please send us your pictures or 3D drawings/2D drawings for us to check all the dimensions.

Specify your required material, surface treatment, quantity and other related information in the email.

We will handle it for you once receiving it soon!

Specifications:

Specifications:1. Item: Sheet metal fabrication dustbin

2. material: steel plate

3. surface treatment: passivating

4. tolerance: +/- 0.1mm

5. process: Punching/pressing through stamping tooling

6. industrial: Metal stamping parts/punching parts/pressing parts

7. certificate: ISO 9001: 2008, SGS, Rohs.

| Detailed Descriptions | |

| Available materials | Steel, Aluminum, Alloy ,Brass, Copper, Bronze, Nylon, Acrylic etc. |

| Process | Laser cutting/stamping, bending, welding, surface treatment |

| Tolerance: | 0.05mm~0.1mm |

| Service | Customized OEM Service |

| DRW format | PDF/CAD/2D/3D/STP etc. |

| Equipment | 8 CNC machines and other assorted facilities |

| Capacity: | 1000pieces per month |

| MOQ: | 1 Piece |

| Machining Scope: | 1). Equipment/Machinery 2). Medical & Technological parts 3). The Automotive/motorcycle parts 4). The telecommunication parts 5). The power tool parts 6). Bicycle parts 7). The agricultural parts 8). Hardware |

| QC System: | 100% inspection before shipment |

| Payment term | T/T ,Pay Pal etc. |

| Surface treatment | Anodizing, zinc/chrome/nickel/silver/gold Plating, Polish, Imitation, Heat treatment etc |

| Packing | 1. Prevent from damage. 2. As customers' requirements, in perfect condition. 3. Send the sample by express, 5 working days. |

| Note: | All parts are custom made according to customer's drawings or samples, no stock. If you have any parts to be made, please feel free to send your kind drawings/samples to us. |

OUR PRODUCING PROCESS:

OUR PRODUCING PROCESS:1. Tooling (Mold) design and Manufacture.

2. Manufacture the parts according to the Stamping Machine.

3. Riveting, Welding or Screw tap according to Customer's require.

4. After finish manufacture process we will test the parts by the Image measurement instrument, Caliper, Angel

Gage etc.

5. After make sure all the dimension can reach customer's require, we will make the surface treatment process.

6. After finish surface treatment we will testing all the parts by worker so that we can make sure the parts

which we sell is 100% qualified.

7. After finish testing we will pack the parts by Vacuum Package Machine.

1. New product development process

1. New product development processGot tooling order and sample order with 50% deposit---Hold a meeting with the relation dept. To ensure the developing schedule---Design mould, fixture and gauge and making them in our factory---mould, fixture and gauge making---producing samples---approved from customer-purchasing material-forging-heat treatment-shot blasting-machining-Inspection-package---delievry

2. Can we visit the factory to conduct an audit?

Yes, you are welcome to visit our factory.

3. How to handle the complains?

If happen any complaints after delivery,please just show us photos and detail compliants points, we will check with the production department and QC department Immediately and give you best solving solution which agreed by both of us,moreover we will bear all the cost (including shipping cost).

All parts are made according to customer's drawings or samples.If you have any parts to be made, please feel free to send your kind drawings/samples to us.Technical drawings including material mark, Product weight, Purchase quantity.The comprehensive information will help us quickly calculate the accurate and reasonable price for you.

You can look through our website to find your interest or email your any questions through below approach! We will reply to you within 12 hours.