Basic Info.

Model NO.

cnc metal parts

Processing Precision

0.01~0.02(mm)

Performance Classification

High-End CNC Machine Tools

Surface Treatment

Sandblasted/Anodized/Plated/Customized

Roughness

Ra0.4

Machine Type

Turned, Milled, Swiss Type, CNC Lathe, CNC Center

Transport Package

Standard International Packing

Specification

Customized size

Trademark

RENYI

Origin

China

Product Description

The basic principle of CNC machining is to convert the designed part model or process diagram into computer recognizable instruction codes, and then transmit these instructions to the CNC machine tool through the computer control system. CNC machine tools automatically control parameters such as tool movement, speed, and cutting depth based on instruction codes for precise machining.

CNC machines are used to automate and control the movement of machine tools, such as mills, lathes, and routers, to perform precision cutting, shaping, and drilling operations on various materials.

Here is a list of materials that are very popular for the machining of parts:

CNC machining is a method of controlling machine tools through computer programs for machining. It is widely used in the manufacturing industry and can efficiently produce various parts and products.

Application:

Our factory:

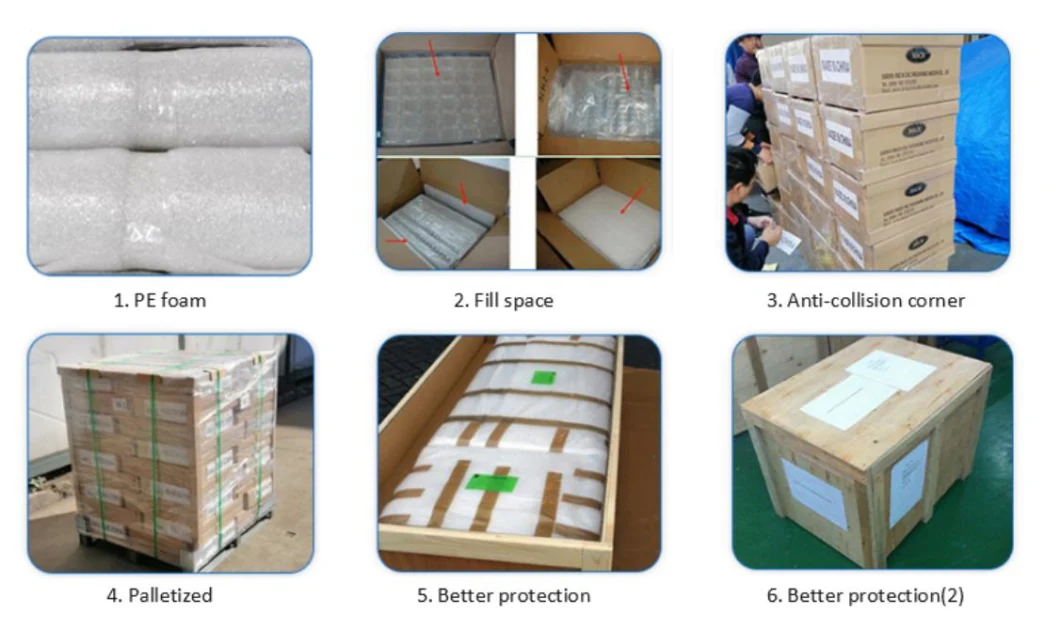

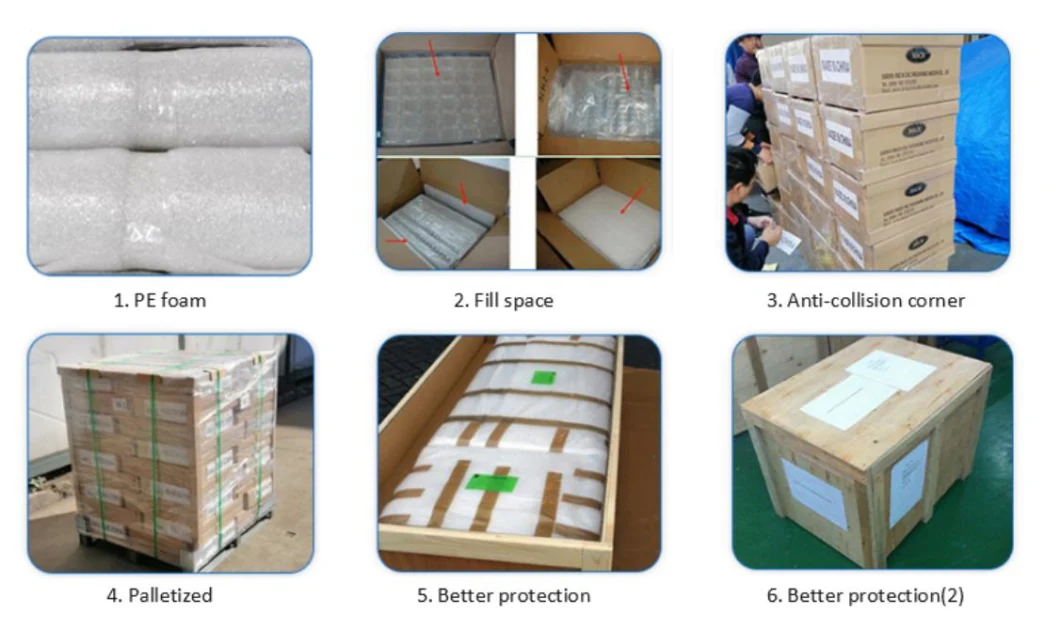

Our package:

CNC machines are used to automate and control the movement of machine tools, such as mills, lathes, and routers, to perform precision cutting, shaping, and drilling operations on various materials.

Here is a list of materials that are very popular for the machining of parts:

| No. | Material |

| 1 | Aluminum Grades 6061,7075 |

| 2 | Stainless Steel- 303, 304, 316L, 410 and 416 |

| 3 | Brass C3604 and C3602 |

| 4 | Copper- T2 |

| 5 | Carbon Steel 12L14, C1045 |

| 6 | Alloy Steel-4130 and 4140 |

| 7 | Titanium-Titanium Grade 5 |

| 8 | Plastics- ABS, Acrylics, Delrin, HDPE, Nylon, and PTFE |

CNC machining is a method of controlling machine tools through computer programs for machining. It is widely used in the manufacturing industry and can efficiently produce various parts and products.

Application:

Our factory:

Quality Control

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details beforethe production line operated

3) Have a full inspection and routing inspection during mass production---In-process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(OQC)

Our package: