- Overview

- Product Description

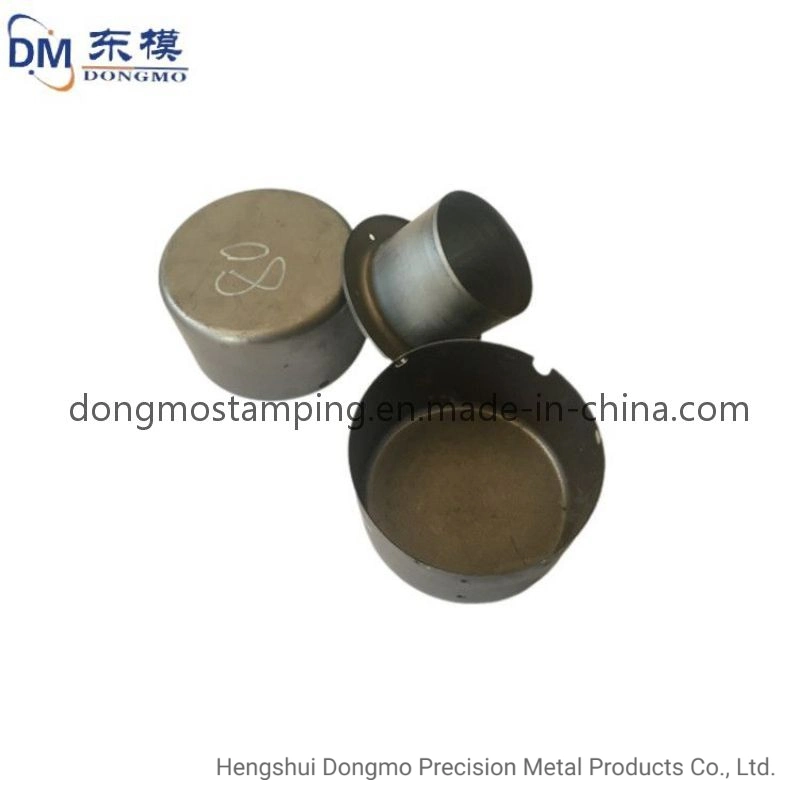

- Detailed Photos

- Company Profile

- Company equipment

- Packaging & Shipping

- FAQ

Basic Info.

Packaging & Delivery

Product Description

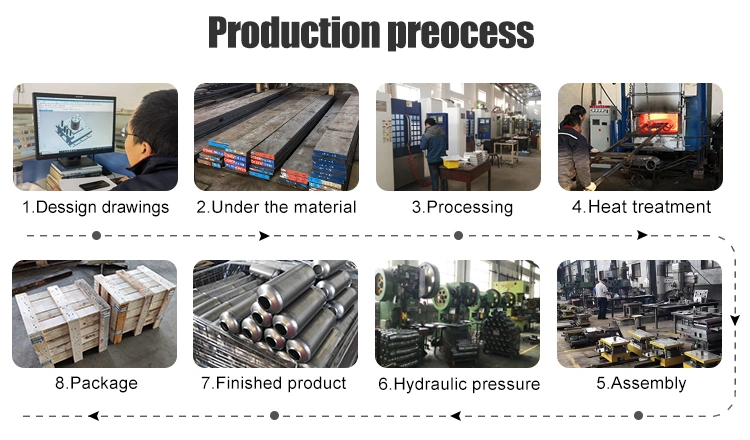

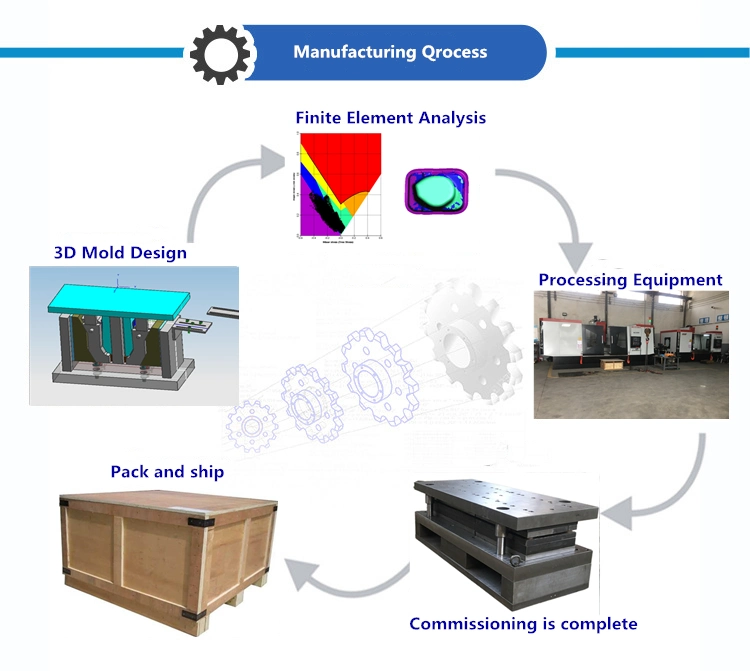

The manufacturing steps of metal stamping parts are generally divided into: stamping parts design, stamping parts development, selection of stamping oil, stamping sheet material, machine tool sheet punching, sheet tapping riveting, sheet three-dimensional bending, workpiece surface treatment of these steps to complete the manufacturing of metal stamping parts; Precision metal stamping process needs to do enough to understand the machine tool and the parameters of the machine tool, according to the process characteristics of CNC punch for comprehensive analysis, so that CNC punch can be reasonable application and full play.

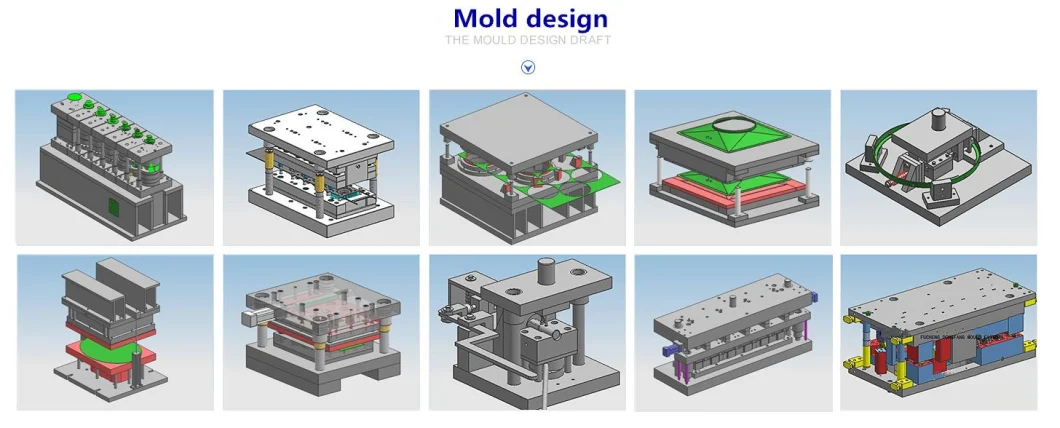

Qroduct Details | Company Information | ||

Qroduct name | Hardware parts | Main products | Stamping die Stamping parts |

Application | hardware | Productive forces | Stamping: 2-3 million pieces/month |

Material | ST14-ST16S | Mould: 40-60 sets/month | |

Standard Parts | MISUMI | Related certificates | ISO9001 |

Template flatness | +/-0.005mm | Package | According to customer requirements |

Quantity | 1 set | Application field | Aviation, automobiles, home appliances, medical, hardware, construction, |

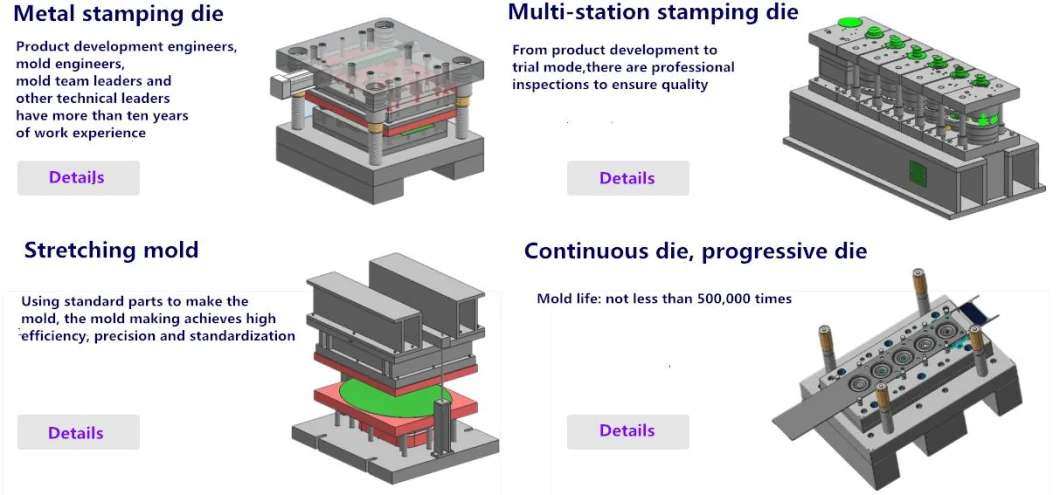

We are a company engaged in the production and sales of stamping molds, various metal molds, metal stamping molds, metal stretching molds, and stainless steel stretching molds. We warmly welcome new and old customers to come and guide us, negotiate cooperation, and achieve win-win innovation!

Mold processing equipment: CNC machining center, CNC wire cutting machine tool, CNC electrical discharge molding machine tool, turning, milling, grinding, and other high-precision processing equipment.

Stamping equipment: 630T, 500T, 315T, 200T, 160T, 100T stretch forming hydraulic presses and various large, medium, and small tonnage punches.

Cutting equipment: 2D CNC laser cutting machine, 3D CNC laser cutting machine.

Frequently asked questions

1. Q: Are you a factory or a trading company?

A: We are a factory, a professional hardware stamping mould and hardware stamping manufacturer.

2. Q: Where is your factory? How can I visit there?

A: Our factory is located in Hengshui City, Hebei Province, China. We warmly welcome customers at home and abroad to visit us!

3. Q: What is the material of your mold?

A: Materials include D2, YG15, DC53, SKD11, D2, SKH-9, SKH-51

4. Q: What is the maximum pressure of your factory?

A: Our factory has 25T, 35T, 45T, 60T, 80T, 110T and 160T punches.

5. Q: How about the machines in your factory?

A: Our factory has a complete set of processing equipment, including large CNC machining center, Sodic EDM processing, imported EDM-HS, radial drilling machine, milling machine, grinding machine, three-dimensional inspection, etc

6. Q: How does your factory do quality control?

A: Quality comes first. METS people have always attached great importance to quality control. For all molds, QC shall regularly measure with three-dimensional measuring equipment.

For a quick reply, please contact us directly via email