- Overview

- Product Description

- Packaging & Shipping

- Company Profile

- FAQ

Basic Info.

Product Description

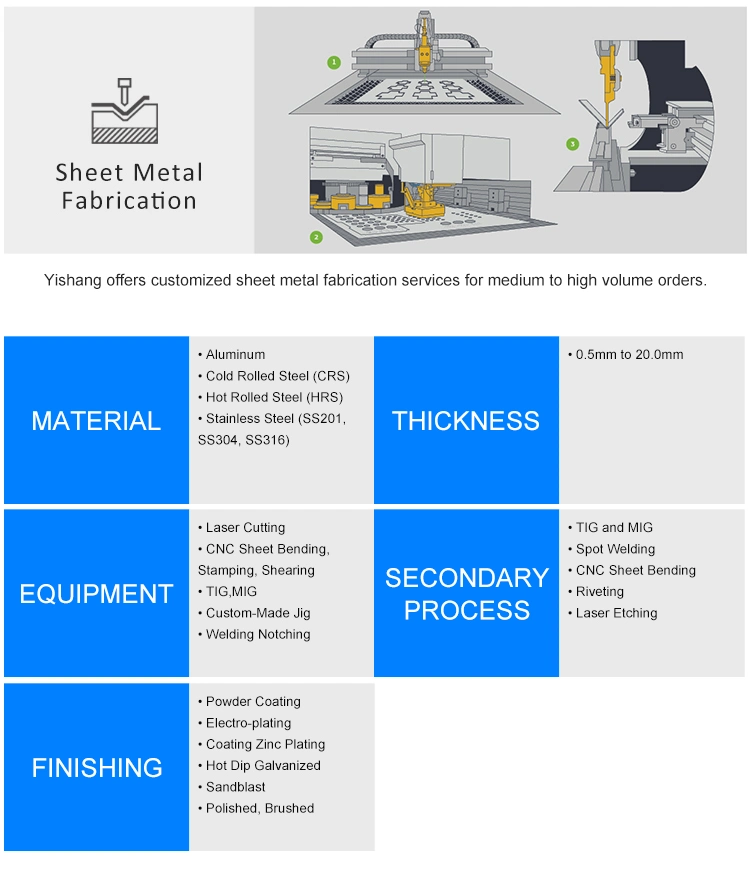

CNC stamping parts sheet metal forming micro stamping bending parts

| Size | customized any size |

| Material: | Aluminum,stainless steel,carbon steel |

| Certificate | ISO9001:2015 |

| Drawing format | 3D/CAD/DWG//STEP/PDF |

| Sample | Pay Sample Fee |

| Advantage | One-stop Solution |

| Quality Control | Professional Inspection |

| Service | OEM sheet metal Fabrication Services |

| Additional | Sample Order and Small Order are acceptable |

| Function | Junction, Distrubution, Electrical, Battery, Control, Monitoring, Outdoor waterproof Enclosure Box |

| Transportation packaging | Can be knock-down packaging or complete packaging. |

Precision CNC Punching Hole

Precision CNC punch is used to punch square holes and circular holes.

Sheet Metal Bending Parts

The 1.0mm stainless steel plate is bent by precision CNC bending machine, and the surface is treated with white powder coating.

The production cycle is fast.

1. Sample: After confirming all product details, complete the sample within 2 working days.

2. Batch: Continue to batch after the first sample is confirmed. Production time is 5-7 days.

(We can provide different production plans for you according to different production processes of different products.)

Packaging

Small chassis regular packaging: foam, plastic bags, and export KAA carton to protect product names from damage.

The packaging method is that each product name is packaged in a carton that can be printed with the buyer's own trademark. A warm welcome to custom packaging configurations.

Each package will be crash tested to ensure it is strong enough and will not cause problems during shipping.

In this way, we can ensure that our customers get the perfect product.

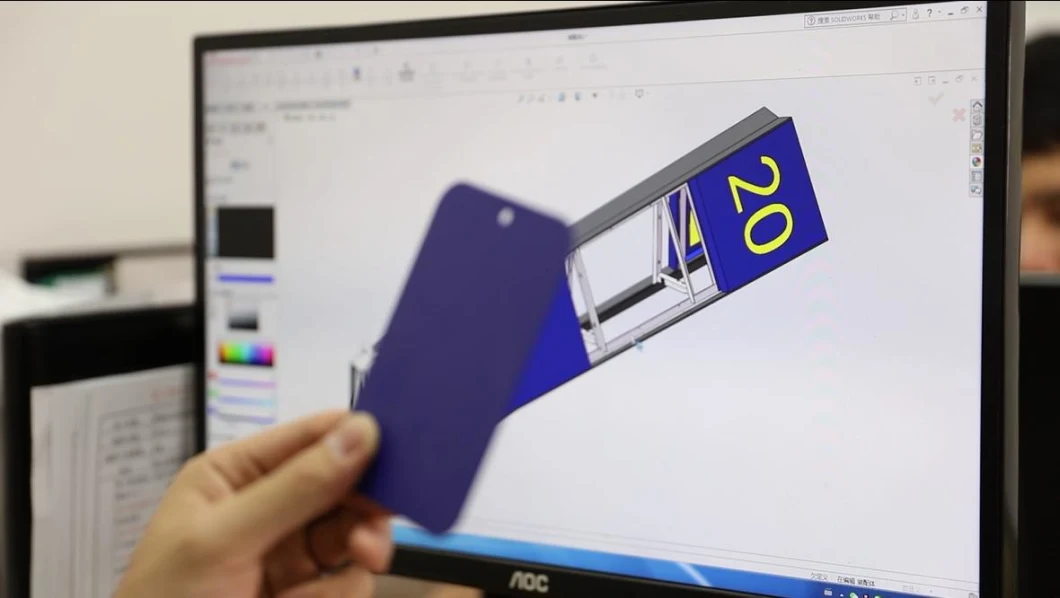

YISHAN Innovation provides a wide range of 2D and 3D CAD drafting services for the product development sector utilising our Solidworks CAD suite.

"Design for Manufacturing"

As a Customized Sheet Metal Design Fabrication ,we provide not only manufacturing service,but also sheet metal design Consulting Service.

Through consulting, we can find out where to cost down but still keep product's quality.

We promise to you that your design can be manufactured just according to your budget and quality request.

First Article Inspection Report: before mass production,each project is examined,evaluated and recorded in detail,and then feedback to customers through our comments.

Provide FAIR hard copy and physical samples.

First sample inspection report:

Inspection dimension inspection report (whether it is the size required by the customer, tolerance range.

Quality test report.

Complete summary instruction.

The inspection report needs to examine the function, assembly, surface treatment and pakaging of the product.

PSI Inspection report

01. Function of the product :Whether it can meet the customer's needs according to the customer's requirements.

02. Assemble: If it is a component. can it be assembled together and used property?

03. Surface treatment: Whether the surface treatment is carried our according to customer's requirements, whether the treatment is in place, and whether there is any missing treatment.

04. packaging: Final inspection before packaging, checking crushed qualified and marks

Q1: Where can I get product & price information?

A: Send us an inquiry e-mail, we will contact you as we receive your mail.

Q2: How long can I get the sample?

A: Depends on your specific items, within 3 - 7 days is required generally.

Q3: What's kinds of information you need for a quote?

A: Kindly please provide the product drawing in PDF, and will be better you can provide in STEP or IGS

Q4: what's the payment terms?

A: We accept 30% as payment deposit when the goods are done, we take photos for your check and you then pay the balance.

Q5: How to deliver the goods?

A: We deliver the products by Alibaba transportation.

Q6: Are you a trading company or factory?

A: We are direct factory with experienced engineers and employees as well as approximate 5,000 square meters workshop area.

Q7: What shall we do if we do not have drawings?

A: Please send your sample to our factory, then we can copy or provide you better solutions. Please send us pictures or drafts

with dimensions (Length, Height, Width), CAD or 3D file will be made for you if placed order.

Q8: Can we get some samples before mass production?

A: Absolutely

Q9: Will my drawings be safe after sending to you?

A: Yes, we will keep them well and not release to the third party without your permission.

Q10: Is it possible to know how are my products going on without visiting your company?

A: We will offer a detailed production schedule and send weekly reports with pictures or videos which show the machining progress.