- Overview

- Machine Specification

- Company Profile

Basic Info.

Product Description

PL Series Vertical Machining Center VMC855/1165/1375

• The machine integrates milling, drilling, boring, and tapping functions.

• It is used to machining metal parts such as aluminum, steel, copper.

• Apply for automotive, aerospace, medical equipment manufacturing, die & mold and machinery component manufacturing, etc.

• High-strength machine bed and moving structure ensure high accuracy and reliability at high speed.

• Superb machining results thanks to the state-of-the-art CNC system

• Fast speed and high precision thanks to the X/Y/Z axis dynamic servo drives

• Provide standard machines, as well as customized options according to your needs.

• Three-axis bearing adopts P4 grade Japanese NSK/NACHI.

• The three-axis screw adopts the C3 grade Taiwan HIWIN.

• The main electrical components adopt the French Schneider.

| Items | Unit | PL855 | PL1165 | PL1375 | |

| Travel | X-axis | mm | 800 | 1100 | 1300 |

| Y-axis | mm | 550 | 650 | 750 | |

| Z-axis | mm | 550 | 600 | 600 | |

| Distance from spindle nose to table surface | mm | 120-670 | 120-720 | 120-720 | |

| Worktable | Size (Length*Width) | mm | 1000×550 | 1200×600 | 1300×700 |

| Max. load | Kg/m2 | 500 | 700 | 800 | |

| T-slot (Number/Width/Center distance) | mm | 5-*18T*90 | 5-*18T*100 | 7-*18T*100 | |

| Spindle | Type | / | Mechanical | Mechanical | Mechanical |

| Power (S1/S6) | kW | 7.5/15 | 11/18.5 | 11/18.5 | |

| Torque (S1/S6) | N.m | 35.5/95.5 | 52.5/118 | 52.5/118 | |

| Max. speed | rpm | 12000 | 12000 | 12000 | |

| Taper | / | BT40/SK40/CAT40 | BT40/SK40/CAT40 | BT40/SK40/CAT40 | |

| Feedrates | Rapid on X/Y/Z | m/min | 48/48/48 | 36/36/36 | 36/36/36 |

| X/Y/Z Cutting Feed Rate | m/min | 1~10000 | |||

| Tool Magazine | Type | / | Disc type | ||

| Capacity | pcs. | 24 | |||

| Tool-to-tool time | sec | 2 | |||

| Dimension | Machine Height | mm | 2600 | 2700 | 3000 |

| Covering Area | mm | 2800*2600 | 2980*3120 | 3340*3160 | |

| Machine Weight | kg | 5500 | 7000 | 7500 | |

WHO WE ARE

PRATIC CNC, founded in 2008, as one of China`s state-level high-tech enterprises, specializes in CNC machining centers and solutions, over the past 14 years of development, Pratic has set up a comprehensive R&D, manufacturing, sales and services network.

Chasing for continuous innovation and state-of-art technology, based on market and customer demand, PRATIC products are widely used in various industries such as automotive, new energy vehicles, aerospace, rail transit, 5G and other machinery manufacturing, serving customers worldwide.

WORKSHOP

PRATIC has two production bases in Guangdong and Jiangsu which a total area of 130000 square meters.

Guangdong base is responsible for producing the long-travel vertical machining centers, light-weight gantry machining centers, horizontal machining centers and automatic production lines.

Jiangsu base is mainly responsible for producing heavy-duty gantry machining centers and ultra-precise machines.

MACHINING SAMPLES

Cooperative Partner

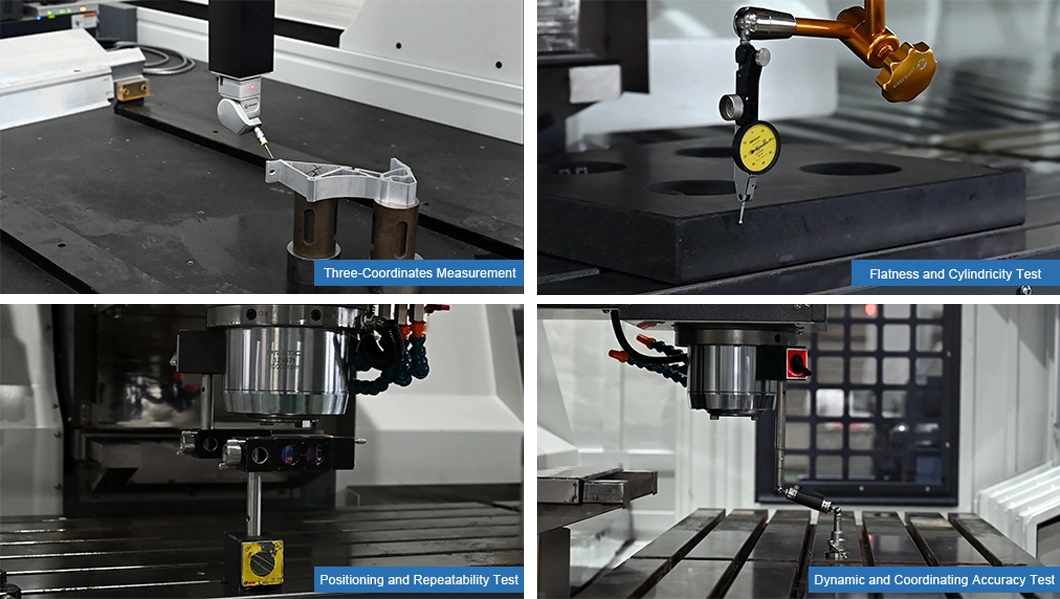

Tests and Quality Assurance

PRATIC is carrying out a strict quality control system of ISO 9001. All procedures from raw materials & components purchasing, machining, adjusting, installing, assembling, to finished machine trial running contain strict tests and inspections to ensure all parts and components are of supreme quality and the finished machines are in 100% perfect condition before delivery to customers.

EXHIBITION

FAQ

Q1: I knew nothing about this machine, what kind of machine i should choose?

Very easy to choose. Just tell us what you want to do by using CNC machining center, then let us give you perfect solutions and suggestions.

Q2: When I got this machine, but I don't know how to use it. What should I do?

We will send videos and manual with the machine. If you still have some doubts, we can talk by telephone or skype and e-mail.

Q3: If some problems happen to this machine during the warranty period, what should I do?

We will supply free parts during the machine warranty period if the machine has some problems. While we also supply free lifelong after-sales service. So any doubts, just let us know, we will give you solutions.

Q4: Before sending me an inquiry on our machine, it is better for you to provide me with the following information

1)Your metal workpiece size. Because in our factory, we have different models according to the working area.

2)Your workpiece materials.

Aluminum/Steel/Iron/Titanium Alloy?

3) You also can send us the drawing of your workpiece, so that we can have a moe careful check and give your more accurate