- Overview

- About us

- ODM| OEM Case

- Fabrication Device

- Laser cutting Machine

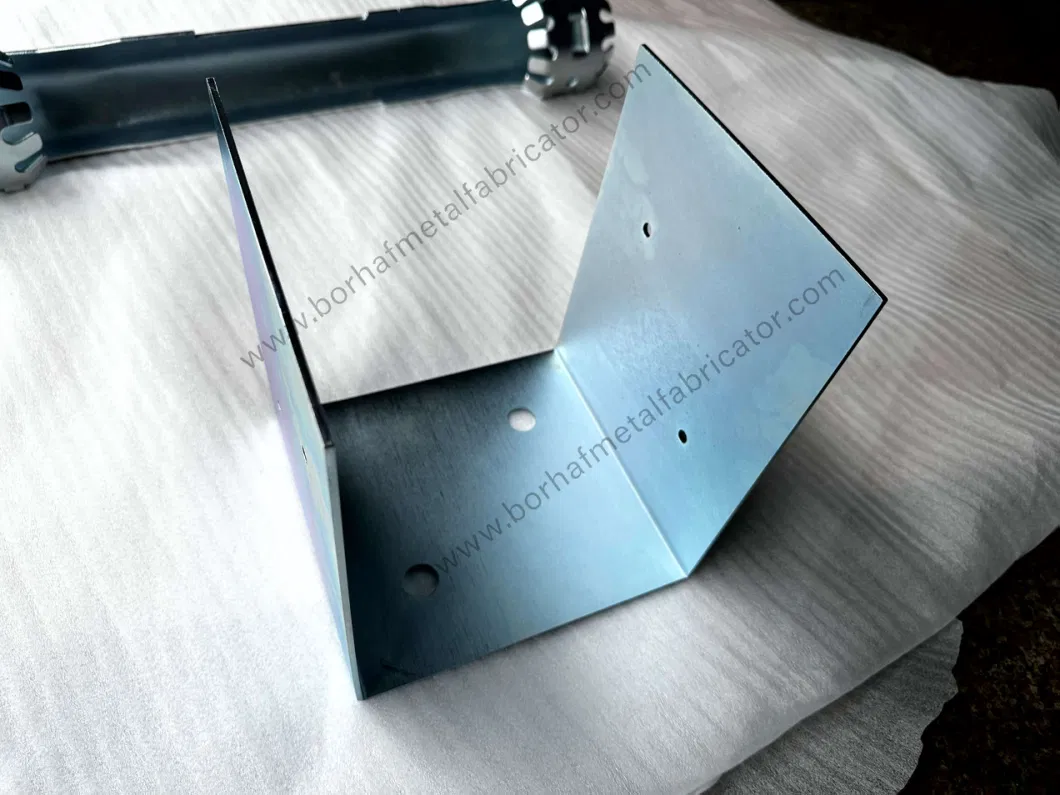

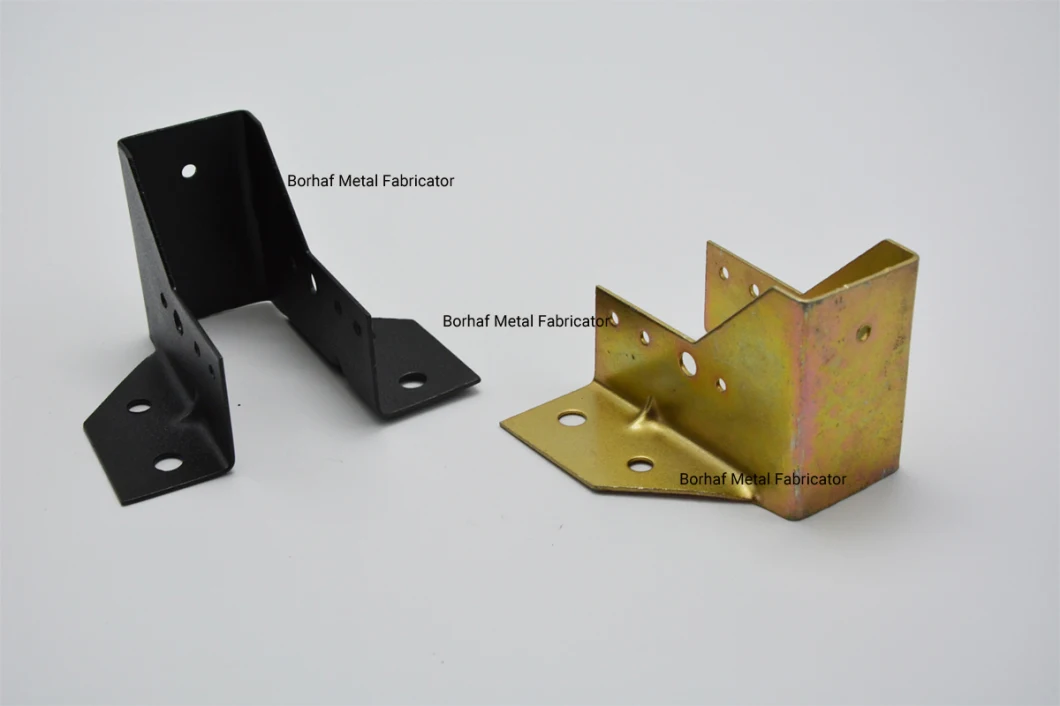

- Related Stamping Parts

- Customer Visit

- FAQ

- Exhibition

Basic Info.

Product Description

About Borhaf Metal Fabricator:

We specialize in all types of sheet metalworking/stamping, and metal pressing and can manufacture custom-pressed metal parts.

Our main production and processing are all types of precision sheet metalworking/ stamping parts, custom-made precision metal stamping, welding assembly parts, and Laser-cutting metal parts.

Our precision sheet stamping parts includes Brackets, Cable anchor brackets, Frame, Vehicle Processing Parts, Automobile Spare Parts, Medical Device Parts, Industrial Machines, Electric Appliance Parts, Furniture Parts, Agricultural Machinery, Electronics, Construction, Machinery Parts, and so on.

Main products: Metal Stamping, Sheet Metalworking, Metal Brackets, Metal Fabricated, metal laser cutting, Mounting plate, Wood connectors, auto parts, Post Brackets, Adjustable Post Base, Sheet Bending, etc

Following that we have developed a set of metal stamping Parts used in the automotive industry and agricultural transport truck| construction industry for customers. Please make a reference.

We have unparalleled competitiveness in the research and development of new products and the manufacture of samples. Please feel free to send us the drawings and our team will work closely with you.

| Product Attribute | Description |

|---|---|

| Drawing Number | The unique identifier for each CAD drawing |

| Material Type | Material used in the part (e.g., stainless steel, aluminum, copper) |

| Thickness | Thickness of the sheet metal |

| Part Dimensions | Length, width, and height of the part |

| Tolerance | Permissible variation in the dimension of the part |

| Bend Radius | Radius of the bend in the sheet metal part |

| Bend Angle | Angle at which the metal is bent |

| Hole Sizes | Diameter of any holes in the part |

| Hole Positions | Location of any holes in the part |

| Surface Finish | Finish on the metal (e.g., polished, galvanized, powder coated) |

| Welding Requirements | Any welding details if applicable |

| Fastening Requirements | Details of any fasteners like bolts or rivets if used |

| Quantity | Number of parts required |

| Revision Number | Identifies the revision of the drawing if changes were made |

above is specified in a CAD drawing or related documentation for sheet metal stamping parts

| Machine Facilities List | |||

| Number | Device Name | Quantity | Remark |

| 1 | 6000W Laser Cutting Machine | 2 | Can Cut Steel Plate to 30mm Thick |

| 2 | 1500W Laser Cutting Machine | 2 | Can Cut Steel Plate to 16mm Thick |

| 3 | 250 Ton CNC Press Brake Machine | 1 | Bending Length can be 3200mm |

| 4 | 500 Ton Oil Hydraulic Machine | 1 | Suit for Deep Stretching |

| 5 | 250 Ton Stamping Machine | 1 | Suit for Stamping and Pressing |

| 6 | 160 Ton Stamping Machine | 3 | Suit for Stamping and Pressing |

| 7 | 125 Ton Stamping Machine | 1 | Suit for Stamping and Pressing |

| 8 | 100 Ton Stamping Machine | 5 | Suit for Stamping and Pressing |

| 9 | 80 Ton Stamping Machine | 1 | Suit for Stamping and Pressing |

| 10 | 63 Ton Stamping Machine | 3 | Suit for Stamping and Pressing |

| 11 | 40 Ton Stamping Machine | 1 | Suit for Stamping and Pressing |

| 12 | 35 Ton Stamping Machine | 1 | Suit for Stamping and Pressing |

| 13 | CNC Pipe Bending Machine | 1 | For Pipe Bending |

| 14 | Polishing Machine | 1 | 2500mm Leng Part Can Be Polished |

| 15 | 16*2500 Plate Cutting Machine | 2 | Can Cut the Steel Platd to 16mm |

| 16 | 6*2500 Plate Cutting Machine | 1 | Can Cut the Steel Platd to 6mm |

| 17 | Carbon Dioxide Protected Welding Machine | 14 | Welding |

| 18 | TIG Welder | 6 | Welding |

| 19 | Saw Blade Cutting Machine | 2 | Cutting |

Laser cutting is one of Borhaf metal fabricator sheet metal profiling processes that directs a high-power laser through optics to cut materials for industrial applications. Laser cutting is both more precise and less energy-consuming than plasma cutting, but has an upper threshold on the thickness of the material being cut. Borhaf's fiber optic lasers offer fiber that can cut many materials including stainless steel, mild steel, copper, brass, titanium, and aluminum. With a 2.5-meter 6.0-meter work table, our laser cutter has ample room for large parts or for nesting multiple jobs on a single piece of sheet metal.

To give you a better understanding of our product range, the following are a few commonly used sheet metal stamping parts for your reference, we can customize your needs, please send the drawings, and we will serve you wholeheartedly.

Q1:You is a trading company or manufacturer?

A1: We are a manufacturer, we complete all the production processes by ourselves. we have many customers in China and we have 11 years export experience.

Q2:Why choose us?

Products are competitively priced, durable, and strong. All our products for long life, toughness, and durability - we're proud of the product we offer. We have a professional team for designing, procurement, QC, and customer service department.

Q3: Can I get the samples?

A3:Yes, the sample is free, you only need to bear express shipping freight or we can send the sample to you by your collect account.

Q4: What do you need to provide a quote?

A4: Please kindly send us the drawing or the sample of your product. Details below should be included, A. Materials B. Surface Finish C. Tolerance D. Quantity E. Delivery terms (Please notice that these are essential for our quoting. Thanks for your understanding and support.)

Q5:Payment and delivery

A5:We accept payment types T/T, L/C, Paypal, and Western Union, The delivery time is about 20-35 days, according to the quantity of your order.

Q5: What materials can you work with?

A5: We have the capability to work with a wide range of metals, including but not limited to stainless steel, aluminum, copper, brass, and various kinds of steel. If you have specific material requirements, feel free to discuss them with us.

Q6: Do you offer custom metal fabrication services?

A6: Yes, we specialize in custom projects and are fully equipped to handle all kinds of metal fabrication tasks such as stamping, bending, welding, and laser cutting. Our team is skilled at bringing unique designs to life and we can accommodate specific needs for any custom job.

Q7: How do you control the quality of your products?

A7: Quality control is crucial to our operations. We have stringent quality checks at every stage of the manufacturing process, from material selection to the final product. We comply with all industry standards and ensure our products meet the highest quality standards before they leave our facility.

Q8: What is your production capacity and lead time?

A8: Our production capacity is flexible and scalable to meet your demands, large or small. The lead time will depend on the complexity and size of the project, but we always strive to deliver within the agreed-upon timeframe. We recommend getting in touch with our team to discuss your specific needs for the most accurate estimate.

Q9: How do you handle shipping and delivery?

A9: We can arrange shipment to any destination worldwide. We handle all the logistics from our end to make sure the products reach you safely and promptly. The shipping cost will be added to the final quote, or you can also arrange pickup or delivery through your own logistics partner if you prefer.

Q10: How can I make a payment?

A10: We accept various forms of payment including bank transfer, Western Union, and PayPal. The specific terms and conditions of payment will be discussed and agreed upon before commencing the project. Your satisfaction and convenience are our top priorities.

Any more questions about the products and some other information, pls contact us feel free.

Interested in high-quality, durable, custom metal parts? Contact us to request a quote, and let us show you the difference our metal fabrication expertise can make. Thank you.